Modern life depends heavily on air conditioning, and the compressor is a crucial component of an air conditioning system. Compressors compress refrigerant gas and circulate it throughout the system to cool the air. In this blog, you’ll get to learn about different AC Compressor Types. They each have their own unique features, functions, and uses.

AC Compressor Function

An AC Compressor acts as the heart of an Air Conditioner. It pumps refrigerant throughout the system, transferring heat from the inside of your home to the outside. When your AC is running, the compressor draws in the refrigerant gas, compresses it and sends it to the condenser coils. The condenser coils release heat outside and send the cooled refrigerant gas back to the evaporator coils inside.

The compressor is what makes the entire air conditioner system work. You should take care of the proper function of the entire system to ensure that your air conditioning system runs properly because it is essential. Regular AC Repairworks and AC servicing can help you keep it running in top condition, and helps you prolong the life of your AC & its compressor.

Also Read: Refrigeration Function: Everything You Need To Know

AC Compressor Types

1. Reciprocating Compressor

Reciprocating AC Compressor is one of the most common AC Compressor Types due to its ease of usage. It uses pistons, which move up & down to compress the refrigerant gas. Since it’s functioning is heavily dependent on Piston, it’s often referred to as Piston Compressor. Usually Reciprocating Compressors contain either one or two pistons, depending upon the size of the unit. The single-piston compressors are smaller and less expensive than the two-piston compressors. Small or medium-sized air conditioners, such as window units and split systems, typically use a reciprocating compressor. They are best suited for residential & commercial ACs.

2. Rotary Compressor

Rotary compressors use a rotating vane or blade that compresses the refrigerant gas. The blade rotates at high speed, creating suction that draws in the gas. The system draws in gas, compresses it and forces it out.

AC systems typically use them for small to medium-sized purposes, whether residential or commercial. Their most common applications are window units, split-system air conditioners, and refrigeration systems. In fact, it is one of the most commonly used AC compressor types. It’s also prominently used in Inverter ACs

3. Scroll Compressor

A scroll compressor is highly efficient, quiet, and provides a smooth operation. It’s commonly used to provide air conditioning, including split-system air conditioners, heat pumps, and rooftop units, in both residential and commercial settings. It features radial movement across the mating parts to reduce mechanical stress on their parts, which makes them much more efficient.

Scroll Compressors have become one of the most popular AC Compressor Types in the HVAC industry since they compress refrigerant gas using two spirals (scrolls) that interlock and move in a circular motion. One scroll stays stationary, while the other rotates around it. A moving scroll compresses a gas that is then pushed through the system as it orbits around the stationary scroll.

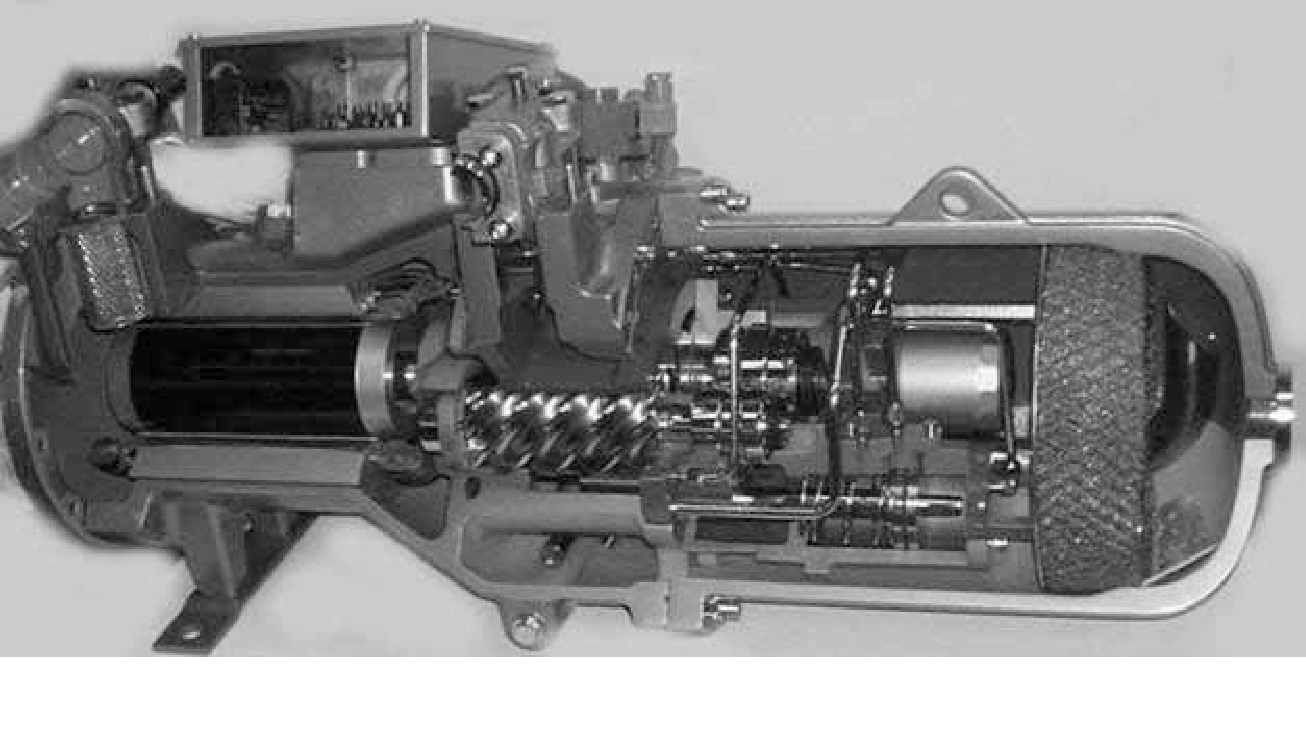

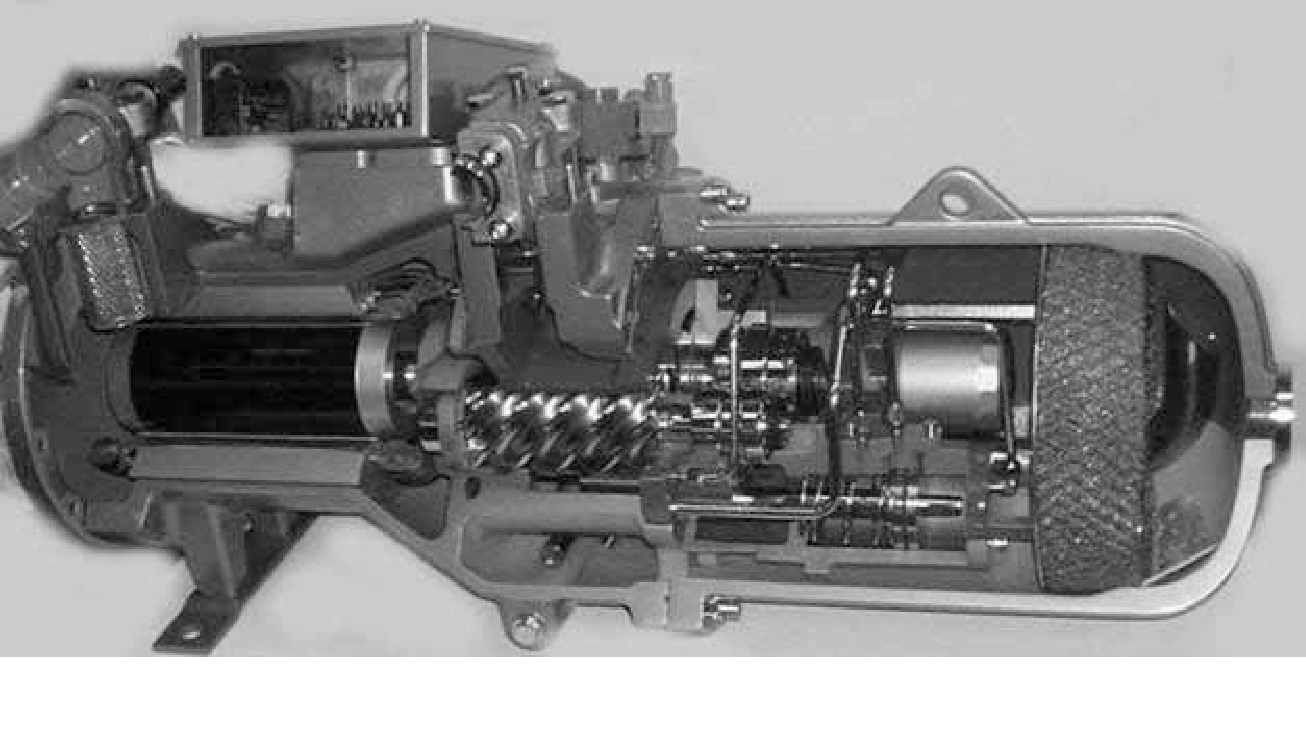

4. Screw Compressor

As opposed to other AC Compressor Types, Screw Compressors do not have valves or rely on mechanical force. It is because of this that rotary screw compressors are able to operate at high speed, while having a smaller footprint and higher flow rates. As a consequence, they have less vibration. They are commonly used in small scale Commercial & Industrial ACs, which are best suited for Hospitals, Factories & Offices.

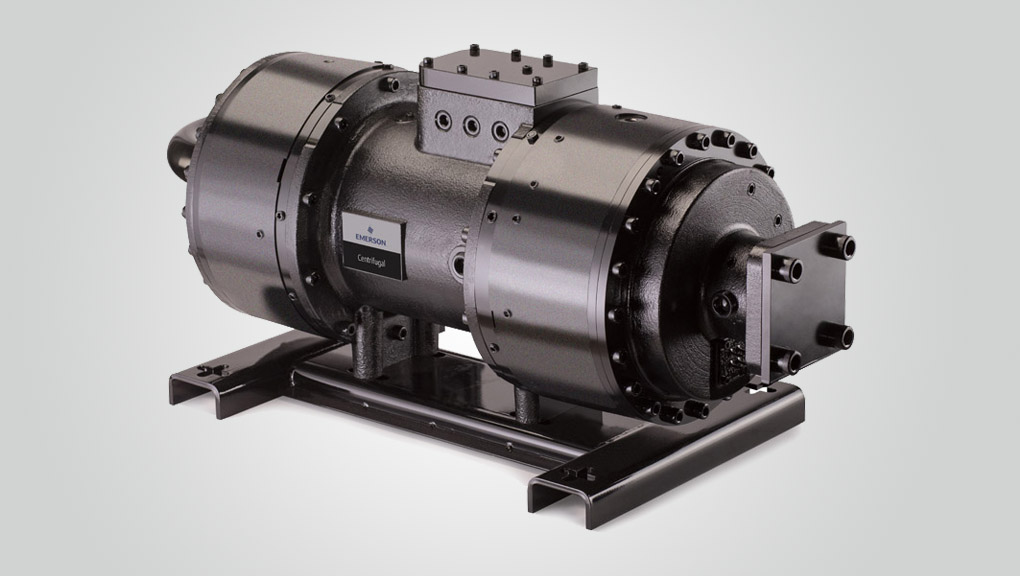

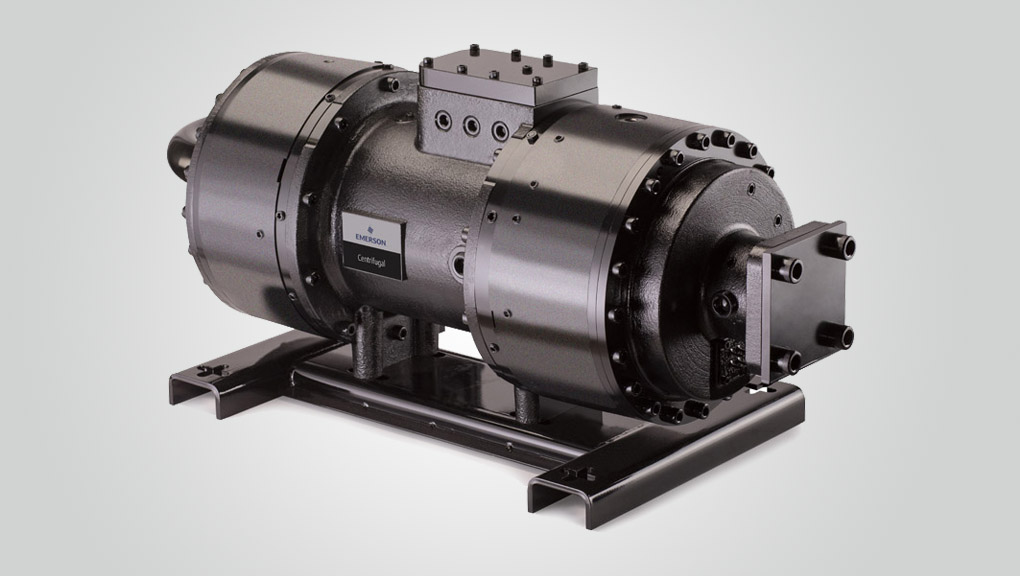

5. Centrifugal Compressor

A centrifugal compressor compresses refrigerant gas using a rotating impeller. The impeller rotates at high speed, creating centrifugal forces that push the gas to the outside of the system, compressing and forcing it out of the system as it moves to the outside. Centrifugal Compressors are suitable for large air conditioners, which are commonly used in large scale commercial & industrial spaces like office buildings, hospitals & manufacturing units.

6. Hermetic Compressor

A hermetic compressor is a self-contained unit with all components housed within a single shell. This includes the motor, crankshaft, piston, cylinder and valves. It’s designed to be airtight, meaning no external parts or supplies are needed for it to operate. This efficient design makes hermetic compressors a popular choice for air conditioning systems. Hermetic compressors are more efficient and require less maintenance, but they may not be able to handle larger workloads. It is one of the most commonly used AC Compressor Types in an Inverter AC.

7. Semi-Hermetic Compressor

Unlike Hermetic Compressor, a semi-hermetic compressor is not completely enclosed. Its motor and crankshaft are encased in a single shell. But it’s also equipped with external parts like valves & connecting rods.

This makes the compressor slightly less efficient than a hermetic compressor, but it’s easier to repair and maintain. Semi-hermetic compressors are also more common in commercial air conditioning systems, as they can handle larger workloads. Semi-hermetic compressors require more maintenance, but they can handle larger workloads.

Conclusion

Innovation is the key to technological advancements. It’s no secret that we’ve made great strides in the field of AC Compressors in order to satisfy the varying demands of the consumers. It has led to the rise of a wide array of AC Compressor types that are available. But this is not the end. In fact, HVAC Manufacturers have already been carved out for people to choose what best meets their needs.

In the end, choosing a compressor will depend on how well you understand what you want and where you are willing to compromise. Rotary compressors are the best choice for ACs with a small capacity, like 10 KW and under, however scroll compressors are a better choice for ACs with a medium capacity, such as 10-50 KW. Similarly if you have a heavy size capacity AC, that has more than 50 KW capacity, then a centrifugal AC compressor is your best bet.